Improving Manufacturing Training with Advanced Technology

A booming economy might be great for everyone. But what is behind the boom? It is often a growing manufacturing sector standing strong at its core. Thanks to the workforce’s expertise, the manufacturing sector grows, and this helps the economy grow tenfold.

At the same time, the industry also faces more than one obstacle frequently, which restricts the sector’s actual ability to perform efficiently.

Moreover, new technologies always bring a fresh set of problems, a lack of certain skills, and other obstacles. Sometimes, some issues are even non-negotiable. At the same time, staying updated with technological developments can be tiring for the workforce, especially if they don’t get the right training or the tools to keep up with industry standards.

On top of that, when an older generation paves the way for a newer, less experienced workforce, a fresh need for training arises. Plus, manufacturers cannot just forget about their safety, considering all the different risks in the manufacturing sector.

The truth is obvious. It is time to start rethinking our training strategies, especially to stay relevant.

It is time to change gears and upgrade our training process. We need to create the most effective training programs and high-impact tools to make the process more convenient, if not better.

So, without wasting time, let’s find out how you can improve manufacturing training with the help of advanced technology.

How To Improve Manufacturing With Advanced Technology?

So, how do you improve manufacturing with the help of advanced technology? Scroll down to find out how.

1. Take Advantage Of Virtual Reality For Immersive Learning

Let’s start with virtual reality and immersive learning. Perhaps one of the best technologies for transforming manufacturing training is currently virtual reality or VR.

More often than not, VR is known for creating a stimulating environment that allows people to fully immerse themselves in scenarios similar to real-life situations. Naturally, this means people can easily learn about dealing with real-life risks.

Additionally, this also means people don’t have to sacrifice safety for the sake of speed. With the help of this approach, workers can finally obtain the training to run machines, identify issues, solve problems fast, and ultimately maintain all safety standards.

From improved safety of workers to increased efficiency, the advantages of VR in manufacturing training are impressive. Moreover, this will also help training your workers without any risks. This, in turn, allows people to repair processes necessary for building competence and confidence without facing any actual consequence in the real world.

Similarly, workers who get VR training are ready to face a new dynamic. Gone are the tired days of watching monotonous videos and turning boring pages of restrictive training programs.

Today, training can be replaced by something that is in the moment, something that is electric. You can easily seize the attention of your workforce with the help of virtual reality and nurture their enthusiasm, ensuring that even the most boring lecture can become something interesting within seconds.

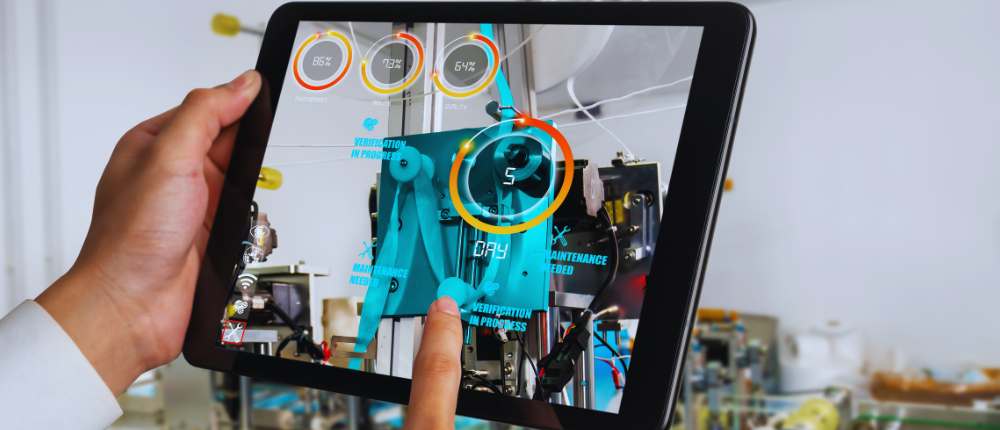

2. Augmented Reality For On-the-Job Support

Have you heard about Augmented Reality or AR? Augmented Reality (AR) extends the real world with digital visuals and information-enhancing real-time operations.

Okay, let’s break it down into simple terms. Just think about a real-world situation – imagine you have a coach on your side while you deal with problems with large machines or handle something tricky. That is exactly what AR does. It sounds great, right?

Moreover, workers who wear AR glasses can obtain real-time information about their equipment, get safety warnings, boost efficiency, and reduce mistakes.

In terms of maintenance training, AR can also project schematics upon real machine parts, helping the tech people through different processes. Moreover, traditional methods cannot keep pace with any type of fast learning that takes place when you get your hands dirty. Plus, you will also troubleshoot with confidence.

3. Artificial Intelligence

With AI at the helm, manufacturing training is morphing into a precision-crafted experience geared to catapult each worker’s skills to the next level.

AI algorithms analyze learner data to tailor training programs to individual needs, adjusting the difficulty levels and providing resources catered to one’s specific learning pace and style. This adaptive tech maximizes training results by focusing on the sweet spot where learners excel and stumble.

For instance, an AI system implemented in an automotive manufacturer assessed operators’ skill levels. It delivered personalized modules that resulted in a noticeable uptick in operational efficiency and reduced incident rates.

Say goodbye to delayed feedback – with AI-driven assessments, learners receive timely input and can swiftly adapt to overcome obstacles and refine their approach.

4. Internet Of Things

When IoT hooks up devices and shares valuable data, manufacturing training gets a serious boost. When IoT injects real-world data into the training mix, the results are exponential – you get scenarios that genuinely resonate and lasting outcomes.

As equipment hums, sensors capture vital performance data, relaying it to trainees in real-time. This transparency reveals how the machine adapts to shifting circumstances.

With IoT on the scene, maintenance trainees can step in and prevent equipment failures before they happen, stopping potential disruptions in their tracks.

When you invest in machinery maintenance, you’re getting more than just extended equipment life – you’re growing a team of experts who can troubleshoot problems, save money, and keep your operations humming.

5. Gamification

Take manufacturing training to the next level by borrowing from the gaming playbook – it’s a winning formula that sparks learners’ interest and stimulates active involvement.

The trick to keeping learners hooked is to inject a healthy dose of rivalry, game-like rules, and a system of scoring points – a formula that works.

Training gets a serious upgrade when you add some game-like elements to the mix – and learners reap the benefits with higher retention rates and a stronger motivation to see it through.

When we compete against ourselves and others, amazing things happen – our skills improve, our confidence soars, and we become more proficient learners.

6. Mobile Learning For Accessibility And Flexibility

Mobile learning, or mLearning, brings training materials to the learner’s fingertips, allowing them to engage in sessions at their convenience.

Manufacturers often face the unexpected – machinery breaks, power outages, or supply chain disruptions – which is why this capability is valuable. Mobile devices enable workers to access training modules directly on the factory floor, enhancing learning opportunities without disrupting their workflow.

Say goodbye to inconvenient training arrangements! Mobile learning adjusts to each employee’s packed schedule, allowing them to learn at their own pace without sacrificing precious work time.

7. Utilizing 3d Printing For Hands-On Experience

3D printing technology in manufacturing training allows for the creation of exact replicas of machine parts or tools used in production.

With this capability, trainees can get their hands dirty in a simulated environment, minus the financial burden and tricky coordination of using actual equipment.

Visualizing complex machinery in 3D creates an immediate connection, sharply reducing the time it takes to understand the inner workings.

By letting trainees mess around with replicated models, this system enables a degree of creative freedom that’s hard to find elsewhere – they can try out unconventional ideas, see what sticks, and refine their masterpieces before taking them to market.

A 3D printing cost calculator is a tool for training programs that utilize 3D printing technology. By accurately estimating the cost of materials, printing time, and energy consumption, these calculators help educators and trainees make informed decisions about their projects.

This is particularly valuable in manufacturing training, where the goal is to replicate real-world production processes as closely as possible.

8. Incorporating Social Learning Platforms

Social learning platforms facilitate collaborative education and knowledge sharing among peers. What if you could crash a lively discussion between fellow trainees, pose tricky questions, and soak up their hard-won expertise?

That’s precisely what happens when you plug into online forums, workspaces, or social platforms engineered for pros. So, talk about a learning jackpot!

When community members come together, a collective energy sparks, amplifying creative solutions and cultivating a culture of learning within the organization.

9. Implementing Manufacturing LMS Software

Learning management systems for manufacturing, such as iTacit, offer context and streamline the whole training process. So, just say goodbye to training programs and the headaches accompanying them.

Moreover, these systems are known for taking care of everything – from basic creation to tracking; it gives you so much time for you to focus on what actually matters. Moreover, these manufacturing training processes are great at managing certificates, analyzing skills, and improving efficiency. That way, it will allow people to help their employees be productive and perform well.

For example, a leading manufacturer of automobiles received help from a learning management software company. After using the LMS, they witnessed a 30% reduction in not just training overheads but also improving their compliance rate.

Additionally, these systems help trainers organize and offer valuable information to fix their programs over a period of time.

And It’s A Wrap!

And that’s a wrap on how you can improve manufacturing training with the help of advanced technology.

So, just think about it…

What if you could build a workforce that is efficient enough in today’s world? What if they are ready to become the change?

That is typically possible when you bring together manufacturing training with advanced tech. Moreover, with the help of such technology, companies can actually build an efficient workforce.

The next generation of training tools is all about performance. They help manufacturers get more done in less time without sacrificing quality or attention to detail. This, in turn, can translate to serious savings and a significant competitive advantage.

***

BM